HOME >> products >> Welding Positioner >> Turning Table

HOME >> products >> Welding Positioner >> Turning Table

Quickly Details:

Type:Welding Turning Table

Brand:MISA

Condition:100% brand new

Model number:HBJS

Capacity:600kg-500,000 kg

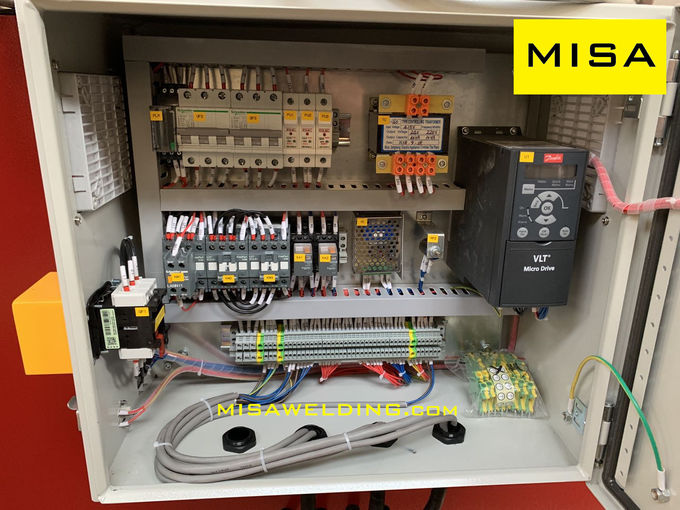

Consist: (1) Main frame (1) Control box with hand panel

Voltage:110V-600V

Painting Color:Yellow & Blue /Yellow & Grey / Yellow & Black / Red&Black

Place of origin:Wuxi , China(Mainland)

Description:

Welding Positioner turning table is mainly used to placed the workpiece in the best position for welding and assembling with the work bench elevating,turning ,tilting ,its series includes tilting ,head and tail stocks ,elevating ,and double turning positioner ,cradle type.The positioner can be supplied for interfacing with robot or welding manipulators,to realize the welding automation.At the same time we can design and customize various type of special positioner according to the technological requirement and different work piece given by the customer.

Kindly Noted:

1. Loading capacity from 0.2ton to 200ton

2. Customer could choose the loading capacity ,diameter of the table

3. Standard voltage is 380V , 50HZ , 3PH. Other voltage please kindly let us know.

4. Control is remote-control box, optional foot switch or wireless control panel

5. If customer need more special requirements ,we’ll study with our engineer.

Applications:

Welding Positioner turning table can be used at automatic welding or manual welding, such as pipe horizontal welding, tube end welding, axle, tray and barrel, it can be wildly used in the pressure vessels equipment, metallurgy, electric power, chemical machine etc industry.

Competitive Advantage:

Electric control system composed of electric cabinet and manual control panel making it easy to operate.

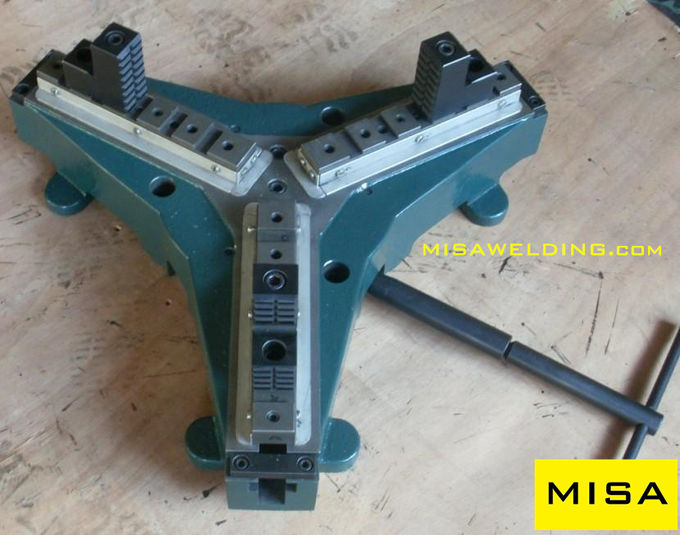

Equipped with slewing bearing which helps increase the loading capacity and makes the rotation smooth.

Worktable is manufactured with six M30T bolt grooves used to clamp and position the work pieces.

Several concentric grooves are processed onto the surface of the worktable to help position the work piece at the center.

Brand using:

﹡ Inverter is made in USA Danfoss / Schneider

﹡ Motor Brand is UK Invertek / WEG / Siemens

﹡ Element is made by Schneider /Siemens/Fuji

﹡ Reducer is made by Kaibo/Guomao

﹡ Bearing is made by NTN / Harbin

Optional:

1. Foot switch

2. Chuck

3. Wireless control panel

Installation and commissioning:

If customer need installation and commissioning,we’ll send 3 workers to customer’s factory ,including one machinery worker,one electrician and one translator.But customer should pay the cost of installation and commissioning.

Why MISA?

360°guarantee makes ordering risk free.

20 years welding machine manufacture experiences.

one-stop service of welding.

OEM service.

Quickly feedback for your problems.